Generator maintenance is essential to the proper functioning of a system, while also minimizing the risk for accidents, damage, and more costly repairs down the line. Additionally, routine maintenance helps to ensure that your generator will run smoothly and efficiently during a power failure.

When you do not maintain your generator, the system can begin to experience damage and complications that can negatively impact its ability to perform properly. Completing regular generator maintenance helps keep an industrial generator operating efficiently, as well as prevent complications or damage to the system.

Preventive maintenance is recommended at least once a year for any industrial generator. Depending on the use and environment the generator is in, two or even three preventive maintenance inspections may be needed each year to ensure the safety and efficiency of the system.

Issues You Risk Without Generator Maintenance

Regularly scheduled preventive maintenance is key to the optimal performance of your generator, as well as reducing risks such as:

1. Dangerous Conditions

Without industrial generator maintenance, a generator may pose safety risks, such as a carbon monoxide leak. As industrial generators run, they emit carbon monoxide, a colorless and odorless gas that poses serious safety risks. In addition to maintaining your generator, you should also check that your carbon monoxide detectors are working properly to ensure you are notified of any potential carbon monoxide emissions.

A poorly maintained generator may also increase the risk of shock or electrocution accidents, especially if the generator is wet or surrounded by excess moisture or water. Customers operating an industrial generator in wet conditions must ensure that the generator receives regular maintenance and is protected from direct contact with moisture to minimize risks.

Another potential hazard is improper storage of fuel or gasoline that has spilled onto engine parts, which can increase the risk of fires. Regular maintenance also enables technicians to identify any weak or compromised aspects of a generator that may increase the risk of a fire or other accident.

2. Expensive Repairs

Postponing regular maintenance can lead to more expensive repairs and costly complications. Skipping routine care does not save money; it leads to more costly repairs that could have been minimized or avoided altogether.

Routine maintenance is essential to detecting minor issues in their earliest stages, preventing them from worsening over time and damaging the generator, and providing the opportunity to address them when they are more cost-effective and simpler to repair. Without regular maintenance, you risk more expensive repairs, as well as serious and sometimes permanent damage to the generator.

3. Lack of Power

One of the most obvious complications an industrial generator can face is not being able to supply power effectively. If a generator is left unattended for extended periods of time, it may lose its efficiency and overall energy capacity. An industrial generator needs routine maintenance to remain functional and provide power during a power failure.

While you may not need power from your generator at this moment, forgetting about servicing your system can cause serious issues with its ability to function when you need it. During a power failure, you want to know you can rely on your generator to operate efficiently and effectively. Maintenance can ensure your generator provides safe, reliable and predictable power during an outage.

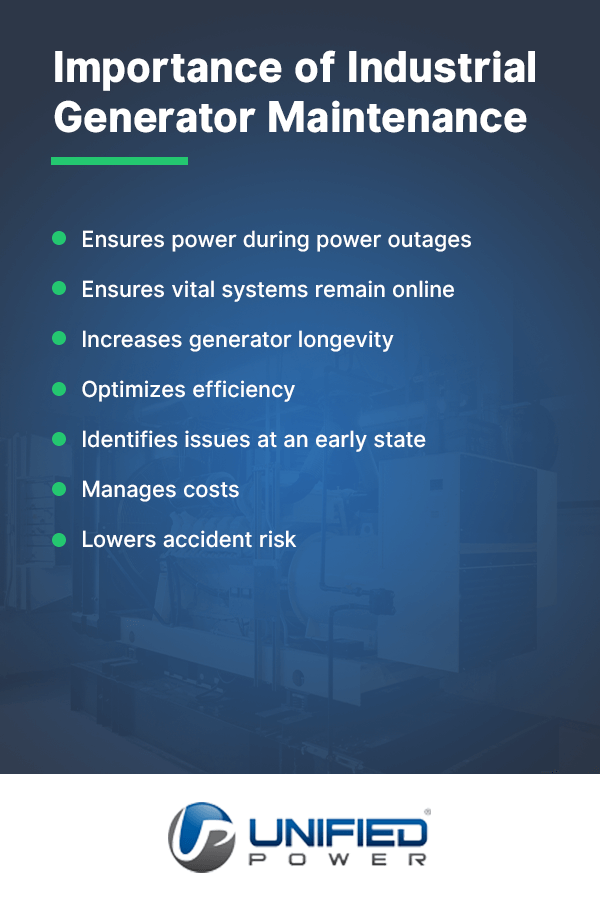

Importance of Industrial Generator Maintenance

It is essential to schedule regular inspections of an industrial generator, including fuel, oil, and coolant samples. Reasons to complete generator maintenance include:

- Maintain power during outages: Industrial generator maintenance helps keep a generator ready to operate at a moment’s notice and provide a reliable source of power during a power failure, keeping critical operations functional.

- Ensure vital systems remain online: Designed to keep critical systems online and functioning, a generator provides a reliable backup power source for critical equipment that must remain up and running at all times.

- Increase generator longevity: Diesel fuel generators are known for providing reliable, long-lasting options. Even though they are durable, routine maintenance helps ensure a generator’s longevity. Regular inspections and minor corrections can avoid larger issues down the line and keep the system functioning properly throughout its expected lifespan.

- Optimize efficiency: A regularly inspected and maintained industrial generator is more likely to run smoothly and experience fewer unforeseen complications or issues. As minor complications are promptly addressed with routine maintenance, generator owners can trust that their unit is finely tuned and dependable.

- Identify issues at an early state: With any generator, minor problems or complications are expected throughout its lifespan. Preventive measures can help minimize the risk of these issues developing. Routine maintenance can also identify an issue at its earliest stage, allowing for a more effective tune-up and preventing the need for a more costly repairs down the line.

- Manage costs: Routine inspections and maintenance for generators is a cost-effective strategy that can help save money over time. The cost of routine maintenance vastly outweighs the expenses associated with letting your generator go without inspection. The longer you go without routine inspections, the more expensive repairs tend to be.

- Lower accident risk: Finally, regular generator maintenance can reduce the risk for potential accidents or injury. Faulty mechanisms or poorly maintained generators increase the likelihood of an accident, including fires, carbon monoxide leaks and other concerns. Ensuring proper ventilation and a properly functioning generator can lower the potential risk for accidents.

How to Determine the Right Generator Maintenance Plan

Choosing the generator maintenance service plan that fits your unique needs can help optimize your industrial generator. The best generator maintenance service plans offer an effective approach to safeguard your equipment and ensure it is performing properly and efficiently. A generator maintenance plan can proactively detect issues and optimize ongoing performance and safety. At Unified Power, we offer the following plans:

Gold Maintenance Service Plans

Routine generator plans are available on a monthly or quarterly basis, depending on your needs. A gold maintenance service plan provides a generator system functional test and an inspection of the automatic transfer switch, as well as:

- Air intake and exhaust system

- Controls and annunciation

- Cooling system

- Gas or diesel fuel systems

- Generator assembly

- Lube oil system

- Starting battery, charging and system

- Generator enclosure, base and room

Platinum Maintenance Service Plans

Platinum maintenance service plans also provide in-depth inspections and routine maintenance to ensure a generator is reliable and operating effectively. Platinum plans include everything in the gold plan, plus:

- Annual lube oil and filter service, in which the engine lube oil and the primary and bypass filters are changed

- Annual fuel system service with fuel filters changed

Contact Unified Power for Generator Maintenance and Repair Services

Unified Power is a leading industrial generator maintenance company dedicated to offering the latest and most advanced generator inspection, maintenance and repair services. We are a premier national critical power service provider for UPS services and various generator maintenance and repair services. Our team of experts offers mission-critical power services and strives to provide the highest level of customer satisfaction possible.